Printed Circuit Board

Prodigy’s component divisions supports global customer’s to manufacture custom Printed Circuit Boards (PCB) from its manufacturing centers in China and Taiwan.

Technologies

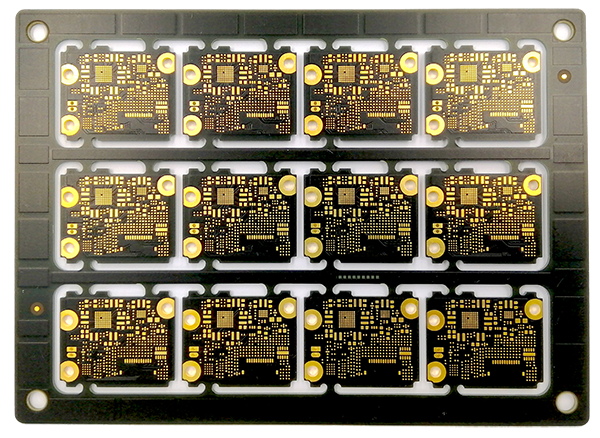

Rigid PCB

Rigid PCBs are produced with a solid material which prevents them from twisting. Once manufactured they can no longer be modified or folded into shapes. Rigid PCBs are well-known for its high density, high reliability, designable, testability and maintainability. They are also relatively less-cost than other types of PCB, which is one of the reason rigid PCBs are widely considered when producing electronic products.

Layer Count: 1 to 64 Layers

Board Thickness: 0.25mm to 10mm

Dimensions: 1092*660mm (max.)

Final Cu Thickness: Inner 12oz/ outer 12oz (max.)

Line Width/ Space: 3mil/ 3mil (min.)

Drilling Diameter:

Aspect Ratio: 15:1

Impedance Control Tolerance: +/- 8%

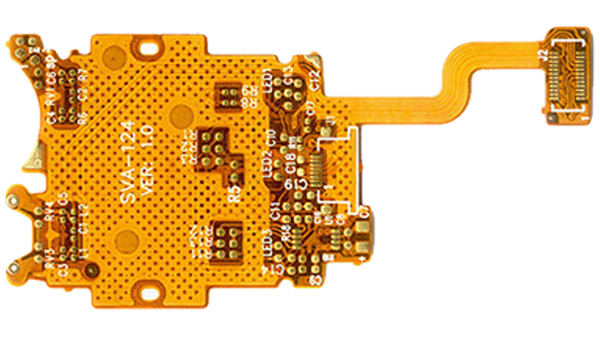

Flexible PCB

Flexible PCBs offer more options and configurations when assembling electronic circuits. They are manufactured with flexible plastic material which enables the ability to fold over edges and wrap around corners, making them become one of the most important components in today’s most advanced electronic products.

Layer Count: 6L

Board Thickness: min. 0.03mm (1L FPC), tolerance min. +/- 0.03mm

Dimensions: 500*650mm (max.), 10*10mm (min.)

Material: FCCL, stiffener, cover-lay

Final Cu Thickness: 1/3-1oz (iner layer base Cu), 1/3-2oz (outer layer base Cu)

Line Width/ Space: 0.075/ 0.075mm finished Cu 0.5oz inner layer, finished Cu 1oz outer layer

Finished Drilling: CNC drill: min. Ø 0.15, laser drill: min. Ø 0.1mm

Aspect Ratio: laser drill: max. 1.2:1, CNC drill: max. 15:1

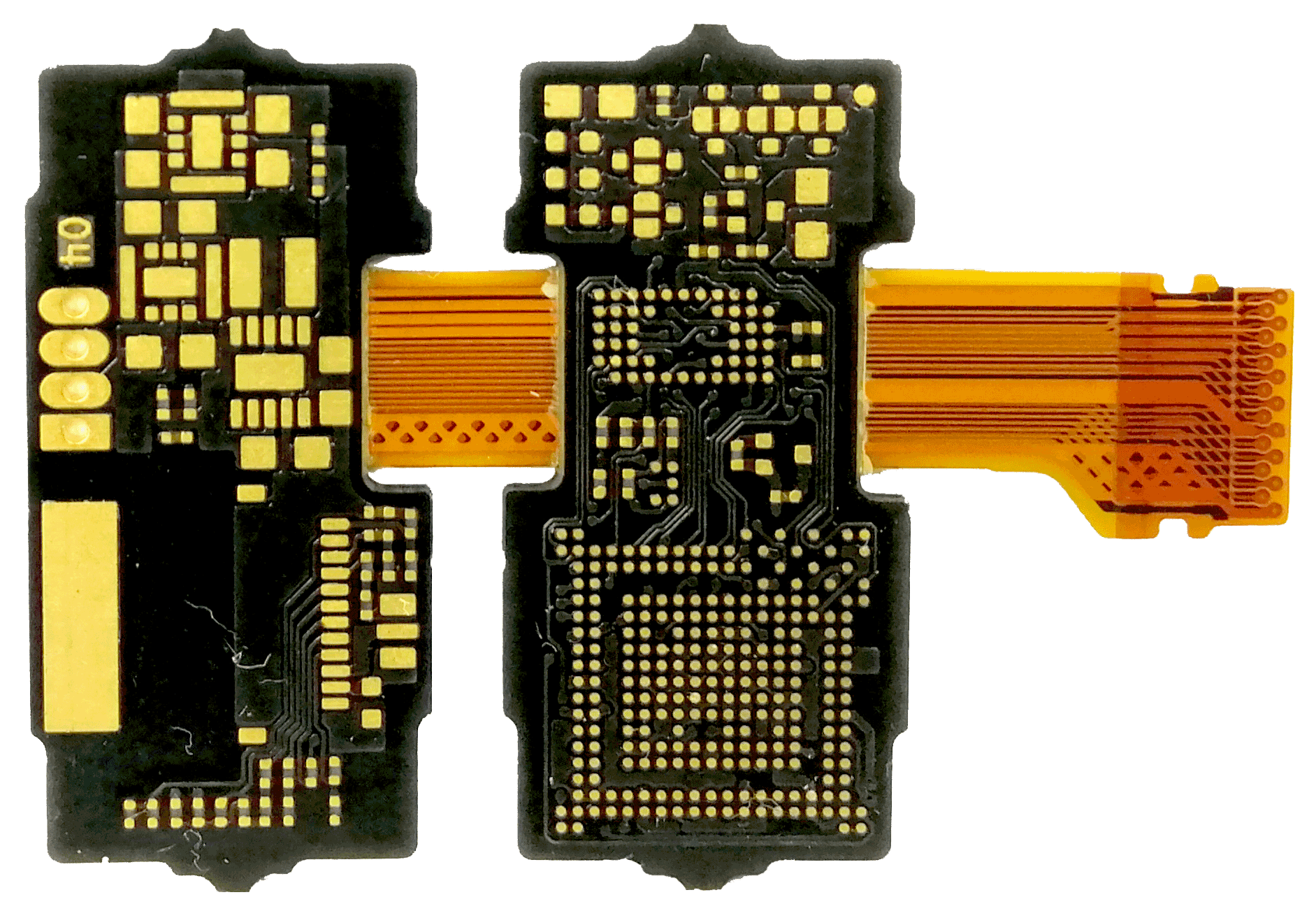

Rigid-Flex PCB

Rigid-Flex PCB is the combination of rigid and flexible board technologies. This allows an application to have a more streamlined design and ability to reduce the overall board size and package weight.

Layer Count: 1 to 64 Layers

Board Thickness: 0.25mm to 10mm

Dimensions: 1092*660mm (max.)

Final Cu Thickness: Inner 12oz/ outer 12oz (max.)

Line Width/ Space: 3mil/ 3mil (min.)

Drilling Diameter:

Aspect Ratio: 15:1

Impedance Control Tolerance: +/- 8%

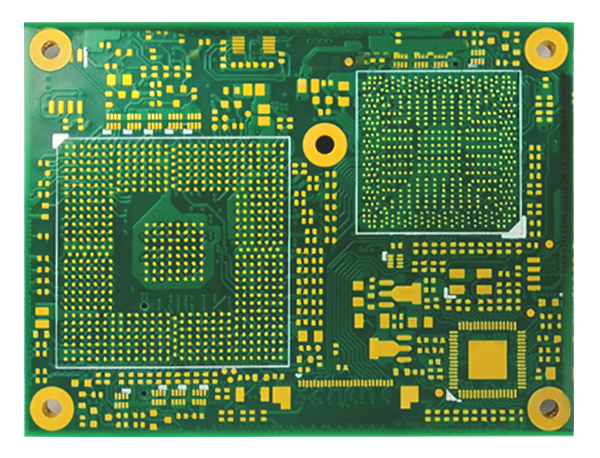

HDI PCB

HDI technology enables a PCB to have higher wiring density, which greatly enhances its electrical performance and optimizes overall package weight and dimension of an equipment.

Layer Count: 48L (4+N+4)

Board Thickness: 0.3mm to 8mm (min. to max.)

Dimensions: 250*330mm (max.)

Final Cu Thickness: Inner 12oz/ outer 12oz (max.)

Line Width/ Space: 3

Drilling Diameter:

Max. Aspect Ratio: 1:1

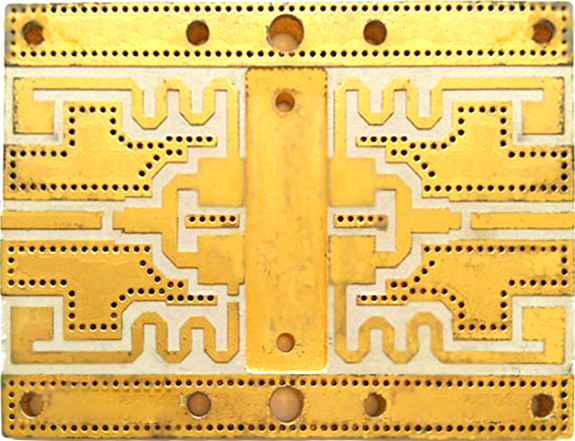

Heavy Copper PCB

Heavy Copper circuit boards are the core components of household appliances, high-tech products, medical or military equipment, due to the fact of the high durability, good heat dissipating and transferring capabilities.

Layer Count: 1 to 64 Layers

Board Thickness: 0.25mm to 10mm

Dimensions: 1092*660mm (max.)

Final Cu Thickness: Inner 12oz/ outer 12oz (max.)

Line Width/ Space: 3mil/ 3mil (min.)

Drilling Diameter:

Aspect Ratio: 15:1

Impedance Control Tolerance: +/- 8%

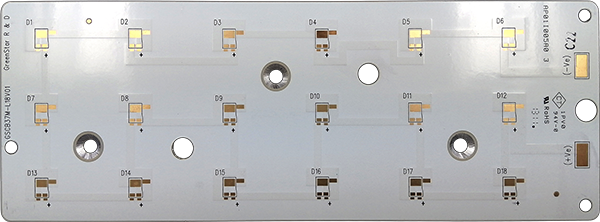

Metal Clad PCB

Metal clad PCB is a type of circuit board that consists of metal laminate and electrically insulated layer. Therefore it adds up extra strength and endurance to the product, best for applications with high temperature and pressure involved.

Layer Count: 1 to 64 Layers

Board Thickness: 0.25mm to 10mm

Dimensions: 1092*660mm (max.)

Final Cu Thickness: Inner 12oz/ outer 12oz (max.)

Line Width/ Space: 3mil/ 3mil (min.)

Drilling Diameter:

Aspect Ratio: 15:1

Impedance Control Tolerance: +/- 8%

Materials